You need to know: The new ‘Water Batteries’ are safer, more affordable, and recyclable.

Although electronics and water don’t normally mix, it turns out that batteries could use a little H2O.

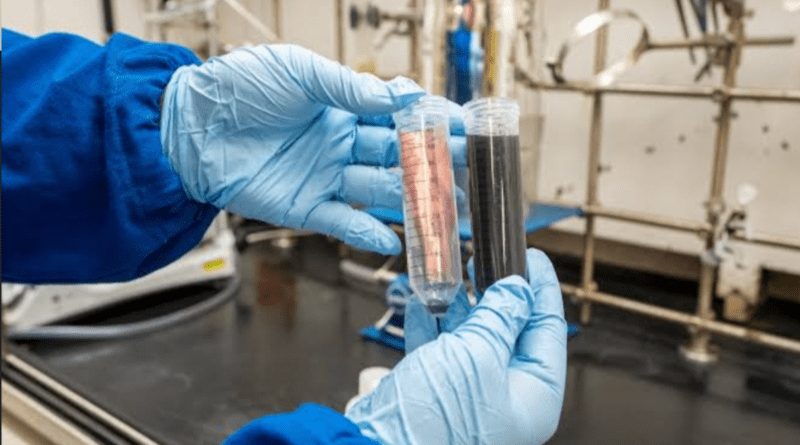

Scientists have created a recyclable “water battery” by substituting water for the dangerous chemical electrolytes used in commercial batteries.

They have also resolved many major problems with the nascent technology, which may provide a safer and more environmentally friendly option. Aqueous metal-ion batteries are the technical term for water batteries. These gadgets are powered by metals like zinc or magnesium, which are less hazardous and less expensive to assemble than the materials used in other battery types.

Electrons in batteries flow from the cathode, or positive end, to the anode, or negative end, storing energy in the process. When electrons go in the opposite direction, they release energy. The purpose of the battery fluid is to transfer electrons between the two ends. Instead of sulfuric acid or lithium salt, the electrolytic fluid in a water battery is simply water with a few salts added.

Most importantly, the group responsible for this most recent development devised a method to stop these water batteries from short-circuiting. This occurs when little, sharp metallic growths known as dendrites develop on the battery’s metal anode and break through the battery compartments.

Lead author and chemical scientist Tianyi Ma of RMIT University in Melbourne, Australia, states that although the new technology is unlikely to replace lithium-ion batteries anytime soon, with more research and development, water batteries could provide a safe alternative to lithium-ion ones in a decade. In severe circumstances, lithium-ion batteries—which are used in everything from electric bikes and vehicles to laptops and phones—can overheat and catch fire. This is a result of the high level of activity of lithium as a metal in an organic electrolyte.

Because of these safety issues, scientists have been working for a long time to create batteries that are identical in longevity and performance but made of different materials. Dendrite growth has been a significant obstacle to the use of aqueous metal-ion batteries.

The researchers used bismuth metal, which oxidizes to generate rust, to coat the zinc anode of the battery in order to prevent this.

As a result, a barrier is formed to prevent dendritic formation.

Lead-acid batteries are utilized in large-scale grid energy storage applications as well as to start gasoline or diesel automobile motors due to their low energy density.

Nevertheless, they need to be recycled at specialized facilities since they contain dangerous acids and lead, which prevents them from being disposed of.

Given anticipated increases in demand for lithium-ion batteries and the metals used to produce them as the globe electrifies its energy infrastructure to phase out fossil fuels and combat climate change, recycling or reusing lithium-ion batteries is therefore of utmost importance. “Addressing end-of-life disposal challenges that consumers, industry, and governments globally face with current energy storage technology, our batteries can be safely disassembled and the materials can be reused or recycled.

Practical uses for the battery idea included the researchers connecting it to a 45-watt solar light and a solar panel so that, after a day’s charge, the light would remain on for 12 hours. More study should be motivated by this small-scale demonstration of the possibility of using “water batteries” for sustainable energy storage.