Spectacular AI Meets The Wonderful Carpet-Weaving Sector In India

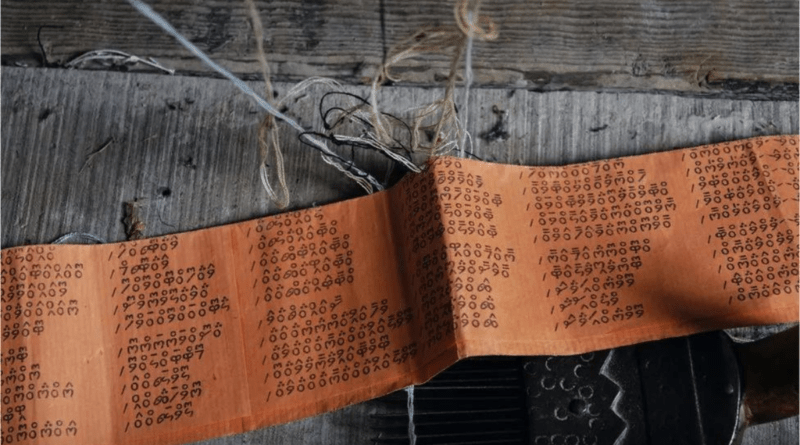

The code, known as talim, has been used for hundreds of years to guide weavers and design carpets. Following in his father’s footsteps, Mohammad Rafiq Sofi began weaving carpets with talim motifs at the age of eight.

Mr. Sofi, who is currently 57, states, “It took me five years to learn how to weave properly.” In his fifty years in business, a lot has changed. According to Mr. Sofi, completing a carpet could take up to six months in the beginning. A carpet would be drawn out by a designer to begin the process. After that, a talim expert would encrypt the design and send little portions of it off to be woven.

For Mr. Sofi and other weavers, the code fragments would be translated, indicating to them the proper location to knot each thread and the colour to employ. Since each segment would only cover a small portion of the carpet, hundreds of weavers and designers would need to collaborate extensively to complete the project.

Errors become challenging to identify and time-consuming to fix as a result of the approach. However, modern computer software has expedited the procedure, enabling Mr. Sofi to complete a carpet in just six weeks. The talim code is now designed and created by computer software, but the weaving and knotting are still done by hand. This allows Mr. Sofi to view the entire design at once rather than just selected portions of it.

Errors that take a long time can be reduced by anticipating possible issues. Director of Handloom & Handicrafts for the government of Jammu and Kashmir, Mehmood Shah, says, “This innovation in handmade carpets is not to disrupt the essence of artistic carpets”

Technology companies that are integrating artificial intelligence into the process are the sources of the most recent innovation. Aby Mathew is the chief operating officer of International Virtual Assistance, a data analysis-focused computer software company.

His organisation is using images of carpets and talim code lines to teach an artificial intelligence (AI) system how to decipher the code.

Mr. Mathew claims that by decoding the talim instructions for the weavers, the AI should speed up manufacturing, even if it is still in the early stages of development and will still require human coders. He predicts that as India’s economy expands, the traditional carpet business will find it difficult to keep up with the growing demand.

Customers’ preferences are changing, and they are increasingly looking for carpets that are stylish, durable, and low maintenance.

Rug Republic was started 32 years ago by Aditya Gupta; it currently employs about 5,000 people and produces up to 15,000 rugs per month. He claims that China and Turkey are fierce competitors for the Indian rug and carpet market; hence, it is imperative for the sector to stay abreast of advancements in manufacturing methods.

“The innovation now is oriented towards creating designs that cannot be copied by machines while still using traditional techniques.”

Rug Republic has implemented innovative technology to detect moisture levels and to design, wash, and dry carpets. In addition to conventional wool, experiments have been conducted with materials such as recycled denim, cotton, and leather. Mr. Gupta still believes in traditional approaches despite all the innovation.

An official identification system that distinguishes authentic hand-knotted Kashmiri carpets has also benefited the industry. Customers can confirm the carpet designer and manufacturing method by scanning a QR code.

Carpet designer Shahnawaz Ahmad adds, “Maybe this trade in handwoven carpets would have died in a few years if the [Handicrafts] department hadn’t taken this step.”

Given the significance of the industry to the local economy, that would have been a setback. It employs over 50,000 people in Jammu and Kashmir, who together create rugs and carpets valued at approximately £36 million ($28 million) annually.

For elderly weavers like Feroz Ahmad Bhat, who has been weaving carpets for thirty years, the advancements in the industry have brought hope.

“When I first started working here, we made good money, and there were a lot of individuals interested. Then there was a period of extremely low salaries. However, as fresh designs have been unveiled, the pace of this effort has resumed. It is now thriving once more.”